Jan 12

Closing the Skills Gap in Manufacturing Through Interactive Training

Manufacturing leaders are under pressure to onboard faster, maintain safety, and preserve institutional knowledge across multiple shifts and facilities. The challenge is not a lack of procedures. It is the lack of consistent, hands-on training that shows employees exactly how work should be performed.

Immersive, interactive tutorials built inside digital twins solve this problem by turning static procedures into standardized, visual experiences. Every learner practices the same steps, sees the same hazards, and follows the same expectations regardless of location or shift.

That consistency is what allows modern manufacturing training to scale.

Immersive, interactive tutorials built inside digital twins solve this problem by turning static procedures into standardized, visual experiences. Every learner practices the same steps, sees the same hazards, and follows the same expectations regardless of location or shift.

That consistency is what allows modern manufacturing training to scale.

Walking Through a Manufacturing Procedure Inside a Digital Twin

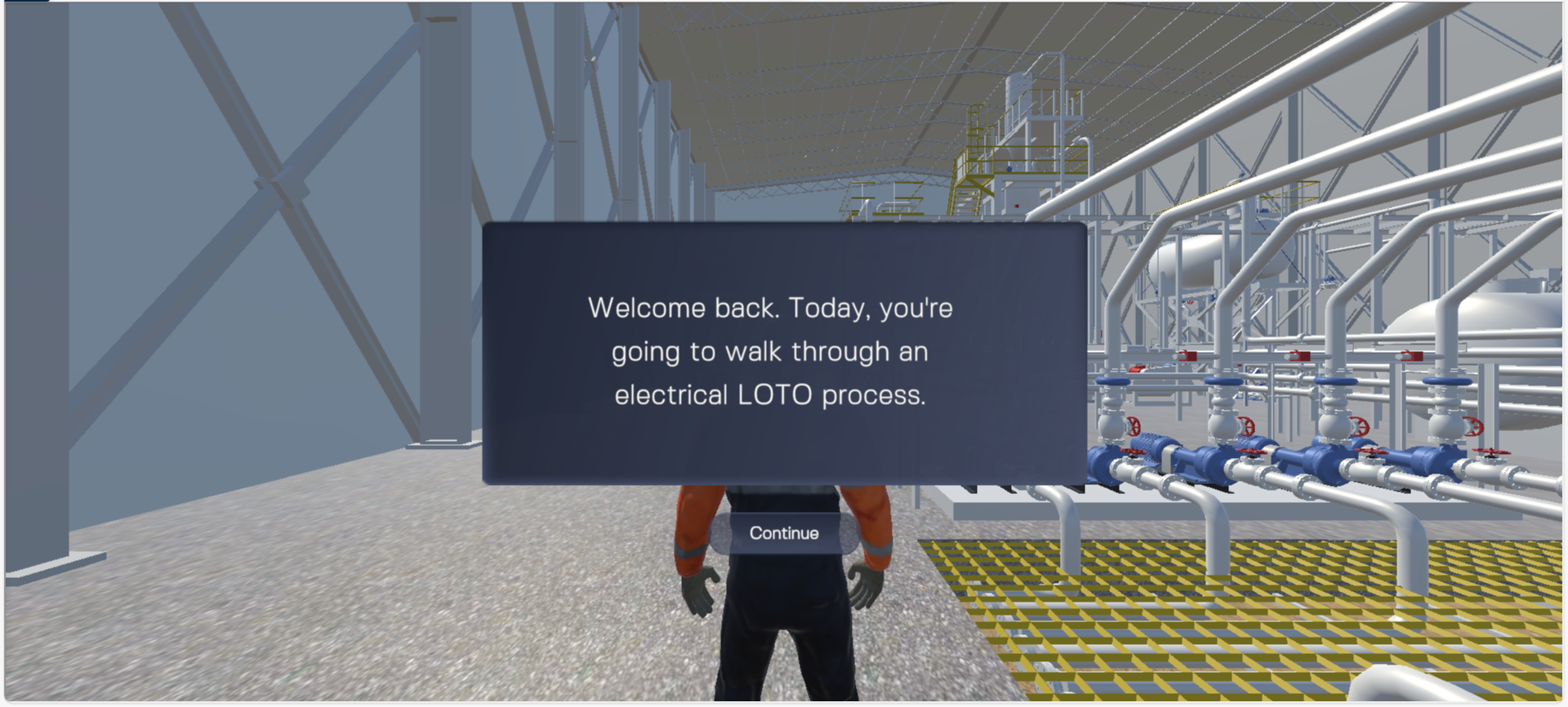

Let’s begin the training by stepping into a digital replica of a manufacturing facility. Today, you’re tasked with completing a lockout/tagout procedure before maintenance begins. Instead of reviewing written steps, you enter the environment and meet your safety mentor, who introduces the pump and outlines the task ahead. You then proceed to perform the procedure exactly as it will be done on the floor.

This scenario opens by orienting you to the machine and surrounding area. The equipment layout comes into view, and you are prompted to locate every energy source connected to the system. Before isolation begins, you identify other employees working nearby who may be affected by the shutdown. You notify them of the lockout/tagout activity and confirm that work can safely pause before moving forward.

You then isolate each energy source in sequence, securing the equipment by locking and tagging the appropriate breaker before proceeding to the HOA switch.

Before maintenance can begin, you complete a final verification step. You attempt to start the equipment inside the simulation to confirm that all energy has been fully isolated. When nothing happens, the system confirms a successful lockout and tagout, and the procedure is cleared to move forward.

Write your awesome label here.

Write your awesome label here.

Throughout the walkthrough, you must complete each step in the correct order to advance, with the system guiding you back if anything is missed. By the end of the scenario, you have completed the full lockout/tagout procedure exactly as it is expected to be performed on the job. Each time you run the training, you follow the same sequence, meet the same requirements, and finish with the same verification, building consistency before you ever touch live equipment.

Write your awesome label here.

Standard Lockout/Tagout Training vs 3-D Digital Twin–Based Training

Traditional lockout/tagout training is built around documentation. Procedures are written, reviewed, and acknowledged, often relying on classroom instruction or on-the-job explanations to bridge the gap between policy and execution. While this approach establishes rules, it leaves much of the learning to interpretation, experience, or memory.

3-D digital twin–based training approaches lockout/tagout differently. Instead of describing the procedure, it allows employees to perform it in a realistic environment that mirrors the actual equipment they will service. Energy sources must be located visually, isolation steps must be completed in the correct sequence, and verification must be performed before the scenario can continue.

In a standard model, consistency depends heavily on the instructor, the shift, or the site. In a digital twin environment, consistency is built into the training itself. Every employee practices the same procedure, in the same order, against the same expectations, regardless of location or experience level.

Why Visual, Scenario-Based Simulations Improve Training Consistency

Manufacturing work is physical, spatial, and sequential. When training reflects that reality, employees build skills faster and retain them longer. Scenario-based tutorials place procedures in context, helping workers understand how actions connect to outcomes and why each step matters before live execution.

This approach improves recall on the job, builds confidence during high-risk or infrequently performed tasks, and reduces variability caused by different trainers or local habits. Because the standard is embedded in the simulation, employees can practice safely and repeatedly, creating a shared understanding of how work is done across shifts and facilities.

Want to see how manufacturers are onboarding faster with Wellsite LMS? Reach out to us here: calendly

Welcome!

Please find on this page your required safety trainings.

Note that you will find both English and Spanish versions of courses. You will only be required to take one or the other.

Note that you will find both English and Spanish versions of courses. You will only be required to take one or the other.