If we learned one thing in 2021, it was that ESG considerations are becoming a real priority to upstream oil and gas companies. If you look at any large cap E&P’s latest investor deck, you are sure to find a few slides on the company’s emission reduction plans.

Now, there’s a lot of talk today about deploying new technology to cut methane emissions – monitoring pads with drones, big data, AI, [insert tech buzzword of choice here]. These technological solutions are all important, but this conversation neglects a critical component of emissions reduction in the oilfield – the frontline field operators who regularly visit the well pads.

Investing in Frontline Employees

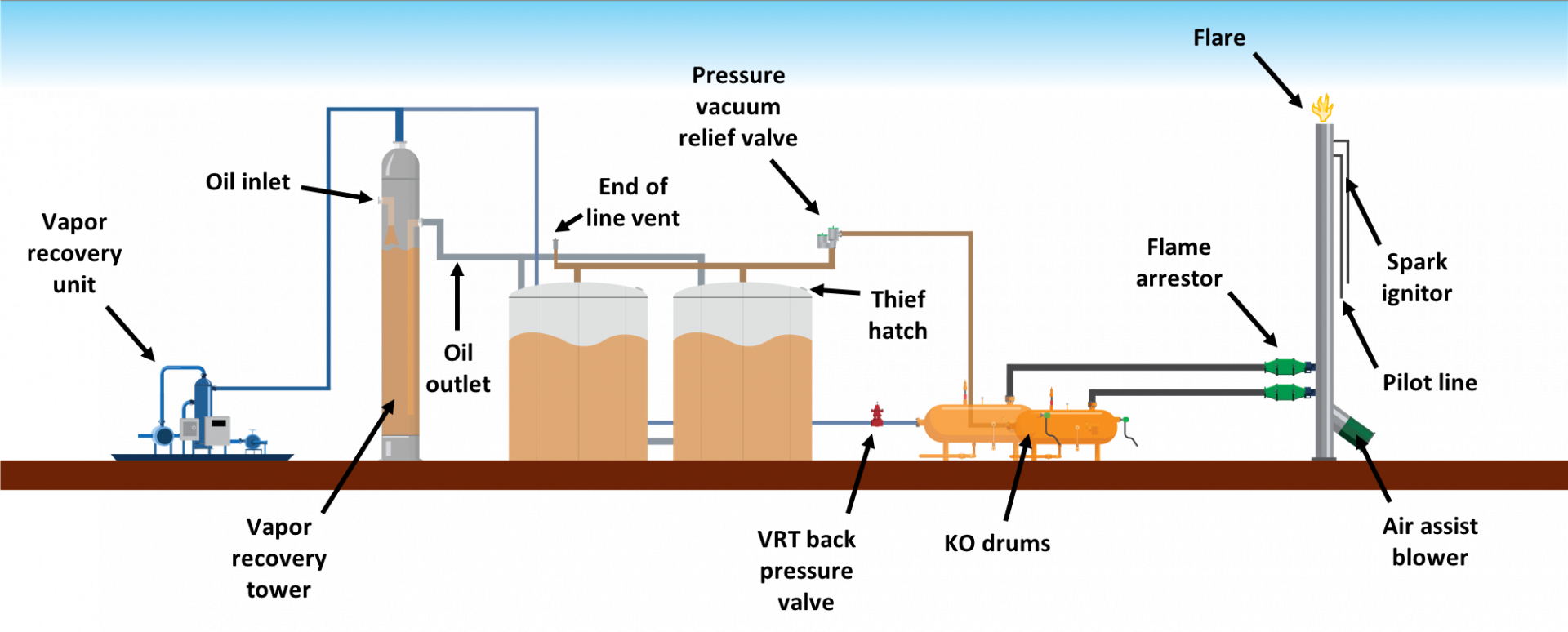

Even though most CEOs are talking about cutting methane emissions, that message isn’t always translated to the folks in the field who can detect & mitigate emissions problems most quickly through operational improvements. And this doesn’t have to be the case – it shouldn’t take a flyover by the EPA to drive home the message to the field that their tanks’ thief hatches shouldn’t be leaking or that their flares need to stay lit continuously or that it's time to call out their vapor recovery compressor tech to walk them through kicking on the VRU. Every operator today should understand how to troubleshoot a typical vapor control system, like the one shown in the image below.

Wellsite Emissions Control Training

Enter Wellsite’s newest training solution: Wellsite Emissions Control. We’ve spent the last year developing a product that provides lease operators & field production staff the training they need to identify and troubleshoot emissions. Specifically, our product:

- Helps operators understand both national and regional environmental regulations without having to read an insanely long legal doc; and

- Provides all operators access to common troubleshooting techniques to mitigate emissions from the most common leak points

As the industry ramps back up and hiring resumes, employees will be expected to have a nuanced understanding of how to minimize emissions quickly and efficiently. The industry is at the point where most folks understand the need to limit high bleed pneumatics, however, there are many more points within the facility that can be further optimized.

Listed below are just a few examples of emissions control lessons that take a long time to learn solely through hands-on field experience.

We can help communicate these learnings (and more) to folks through interactive, easy-to-understand modules that can also be used as reference tools in the field.

Play around with the amount of backpressure on a VRT in the exercise below to see how it affects the tower's liquid level and the tank's flash volume!

- Optimizing pressure set points at the vapor recovery tower to minimize tank flashing

- Understanding how various vent devices should work together on the tank vent header

- Looking for restrictions in the flare line before calling out a maintenance crew to change out thief hatch gaskets

We can help communicate these learnings (and more) to folks through interactive, easy-to-understand modules that can also be used as reference tools in the field.

Play around with the amount of backpressure on a VRT in the exercise below to see how it affects the tower's liquid level and the tank's flash volume!

The oil and gas industry is clearly working to improve its emissions profile. As part of this effort, it is critical to provide frontline field staff with the resources they need to understand regulations and cut emissions based on those standards. By doing so, companies can protect against regulations (or at least demonstrate the field’s knowledge of emissions reduction efforts to regulators), show investors their field employees’ commitment to corporate ESG goals, and improve their bottom line by increasing gas capture rates and decreasing environmental incidents.