Jan 23

The Power of Digital Twins Across Industries

Every industry has its own risks, workflows, and training challenges. Even within the same sector, two facilities can operate very differently based on layout, equipment, staffing, and regulatory requirements.

That is why safety and operations training cannot be one size fits all.

Digital twins offer a different approach. Instead of forcing organizations into a standard training model, they create a virtual version of each facility so people can train inside the environment they actually work in. The value comes from how that environment can be used in different ways depending on what matters most to each organization.

Different Industries, Different Priorities

Digital twins do not solve the same problem for every company. They adapt to the specific needs of each operation.

Process Manufacturing

In process manufacturing industries (such as oil and gas, or chemicals), training often centers on procedural accuracy and risk management. Workers interact with complex systems where the order of operations matters.

A digital twin can replicate equipment such as compressors, separators, pump skids, and valves. Operators can practice scenarios including lockout/tagout, equipment isolation, and startup/shutdown within a virtual version of their actual facility.

This allows teams to reinforce correct sequencing while giving workers a safe place to understand how individual actions affect the larger system.

Machine Manufacturing

In manufacturing environments, consistency and precision are often the priority. Small deviations in how equipment is set up or maintained can lead to quality issues or unplanned downtime.

A digital twin can model production lines, conveyors, control panels, and safety interlocks. Technicians can train on machine startup, calibration, maintenance procedures, and changeovers while seeing how their work impacts downstream processes.

Because the training reflects the real machines on the floor, organizations can reduce variability between shifts and speed up onboarding for new technicians.

Construction

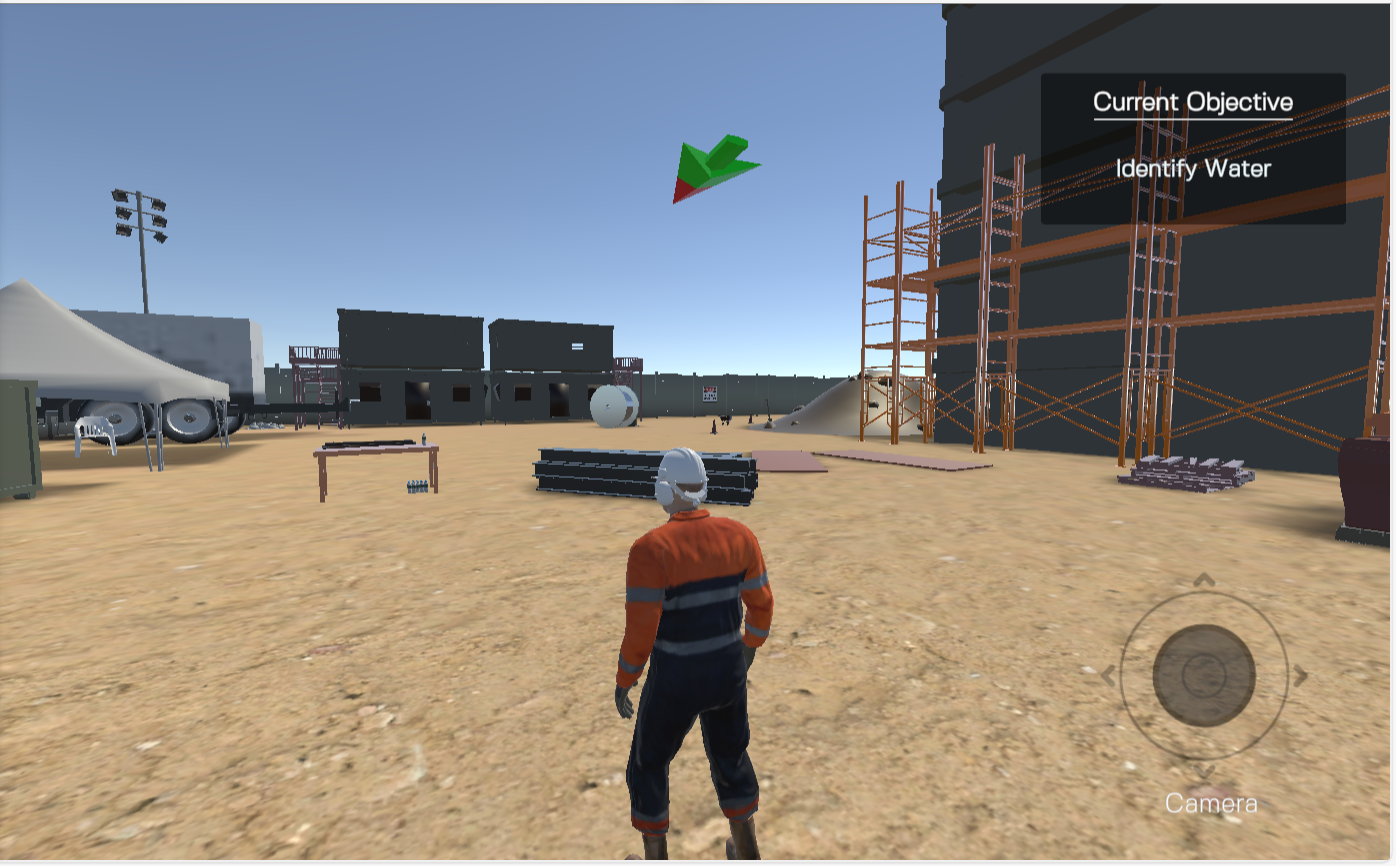

Construction sites are constantly changing, which makes it difficult to prepare workers using static training materials.

A digital twin can simulate job sites that include scaffolding, excavations, cranes, lifts, temporary power, and material staging areas. Crews can walk through these environments to identify fall hazards, equipment conflicts, and access issues before work begins.

This type of training helps improve awareness and decision making, especially during high-risk phases of a project.

Emergency Response and Active Threat Training

Write your awesome label here.

Some of the most important training scenarios are not tied to one industry.

Emergency response, evacuation, and active threat situations can affect offices, plants, warehouses, and job sites alike.

Digital twins allow organizations to simulate these events inside their own buildings and facilities. Employees can practice evacuation routes, shelter locations, and communication protocols within a virtual version of the spaces they use every day.

This makes emergency training more realistic and more memorable than generic videos or slide decks.

One Approach, Many Uses

What makes digital twins powerful is not that they provide one perfect training solution. It is that they provide a flexible environment that can support many different types of training.

A single platform can support procedural training, safety walkthroughs, emergency response drills, onboarding, and compliance tracking, all tailored to each facility.

This allows organizations of any size to focus on the scenarios that matter most to them, whether that is preventing equipment damage, reducing safety incidents, or preparing for rare but high impact events.

Why This Matters

When training reflects the real-world people work in, it becomes easier to understand, easier to remember, and easier to apply.

Digital twins give organizations a way to bring their own facilities, equipment, and risks into the training process instead of relying on generic content.

That is why more companies across many industries are exploring digital twin based training to improve safety, performance, and preparedness.

Want to see how digital twins create safer, smarter worksites in every sector? Reach out to us here: calendly

Welcome!

Please find on this page your required safety trainings.

Note that you will find both English and Spanish versions of courses. You will only be required to take one or the other.

Note that you will find both English and Spanish versions of courses. You will only be required to take one or the other.