A question we often receive is how companies should structure the delivery of their training programs. Training departments do not want to overwhelm their students during day one orientation with content too complex, yet they also need to ensure that employees have the necessary knowledge execute on their roles efficiently.

Our customers appreciate the breadth and depth of our content across various field operations, but still need to make sure it is delivered in a logical and progressive manner. This led us to develop a lease operator training curriculum that increases in difficulty and aligns with the competencies operators need as they advance through their careers.

Over the years we have worked with our customers to refine this curriculum and have deployed it across several basins. Here we detail the training curriculum's overall framework, content, and typical results we see once it is deployed.

Our customers appreciate the breadth and depth of our content across various field operations, but still need to make sure it is delivered in a logical and progressive manner. This led us to develop a lease operator training curriculum that increases in difficulty and aligns with the competencies operators need as they advance through their careers.

Over the years we have worked with our customers to refine this curriculum and have deployed it across several basins. Here we detail the training curriculum's overall framework, content, and typical results we see once it is deployed.

Progression Curriculum

We have worked with thousands of field operators with different experience levels to curate the content within our curriculum. We've listened to feedback across basins to ensure the program complements an operator's typical career progression and responsibilities as they advance in their careers. Below is a more detailed overview of the types of content users experience in each level of our training framework.

Level 1 - 4 Lease Operator Training Curriculum

Level 1

Focuses on production basics and surface equipment, with general overviews of common artificial lift types.

Level 1 training aims to help operators with no prior knowledge safely maintain production and also troubleshoot basic issues in the field.

Level 1 training aims to help operators with no prior knowledge safely maintain production and also troubleshoot basic issues in the field.

Write your awesome label here.

Write your awesome label here.

Level 2

The next level is designed to equip operators to effectively troubleshoot issues at the surface.

This is achieved by understanding the root cause of common surface issues, gas and liquid measurement device operations, and a more holistic understanding of common lift types like rod pumps, gas lift, plunger lift, and ESPs.

This is achieved by understanding the root cause of common surface issues, gas and liquid measurement device operations, and a more holistic understanding of common lift types like rod pumps, gas lift, plunger lift, and ESPs.

Level 3

Level 3 builds on the prior modules to target more detailed subsurface troubleshooting and bringing on new wells.

This level includes downhole card interpretation, common issues with plunger lift, and typical gas lift troubleshooting scenarios. The user also receives content on additional higher level field ops, such as flowback, facility commissioning, and pipeline operations.

This level includes downhole card interpretation, common issues with plunger lift, and typical gas lift troubleshooting scenarios. The user also receives content on additional higher level field ops, such as flowback, facility commissioning, and pipeline operations.

Write your awesome label here.

Write your awesome label here.

Level 4

Level 4 covers typical special projects that a more senior technician or assistant foreman may be responsible for managing.

This training is to support senior field employees as they move into handling chemical programs, deal with corrosion issues, and work with 3rd party takeaway providers at SWDs, compressor stations, and oil gathering facilities.

This training is to support senior field employees as they move into handling chemical programs, deal with corrosion issues, and work with 3rd party takeaway providers at SWDs, compressor stations, and oil gathering facilities.

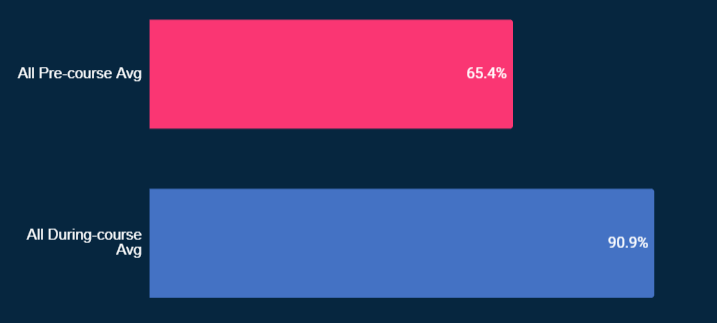

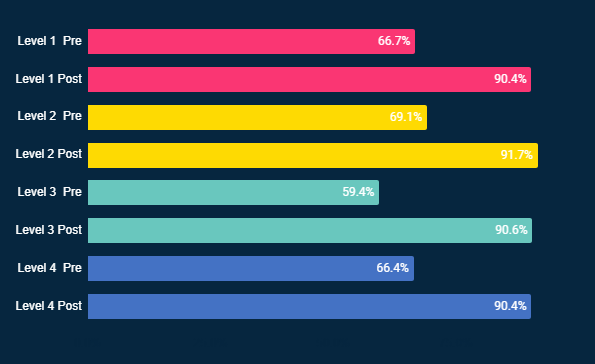

The statistics provide a glimpse into the effects training can have in closing knowledge gaps across a field ops workforce. Our operators averaged 91% scores during-course assessments compared to a 65% before they took the level 1-4 progression curriculum. Our 26% increase is well reflected across all 4 levels.

How can Wellsite LMS help?

If you found any of this information helpful, you would probably be interested in seeing more of our products found in the solutions tab or by contacting us. We cover all this information and more, so we would love to get in touch!