Spills suck. Let’s face it: spills from production operations are the last thing anyone wants to deal with when they wake up and head to work.

We try our best to maintain equipment as well as possible, invest in materials and chemicals to prevent corrosion, and train our people to catch spills early or before they happen. But even after all this money is spent we still have plenty of leaks, spills, releases, etc.

We try our best to maintain equipment as well as possible, invest in materials and chemicals to prevent corrosion, and train our people to catch spills early or before they happen. But even after all this money is spent we still have plenty of leaks, spills, releases, etc.

Spill intensity increases following a downturn

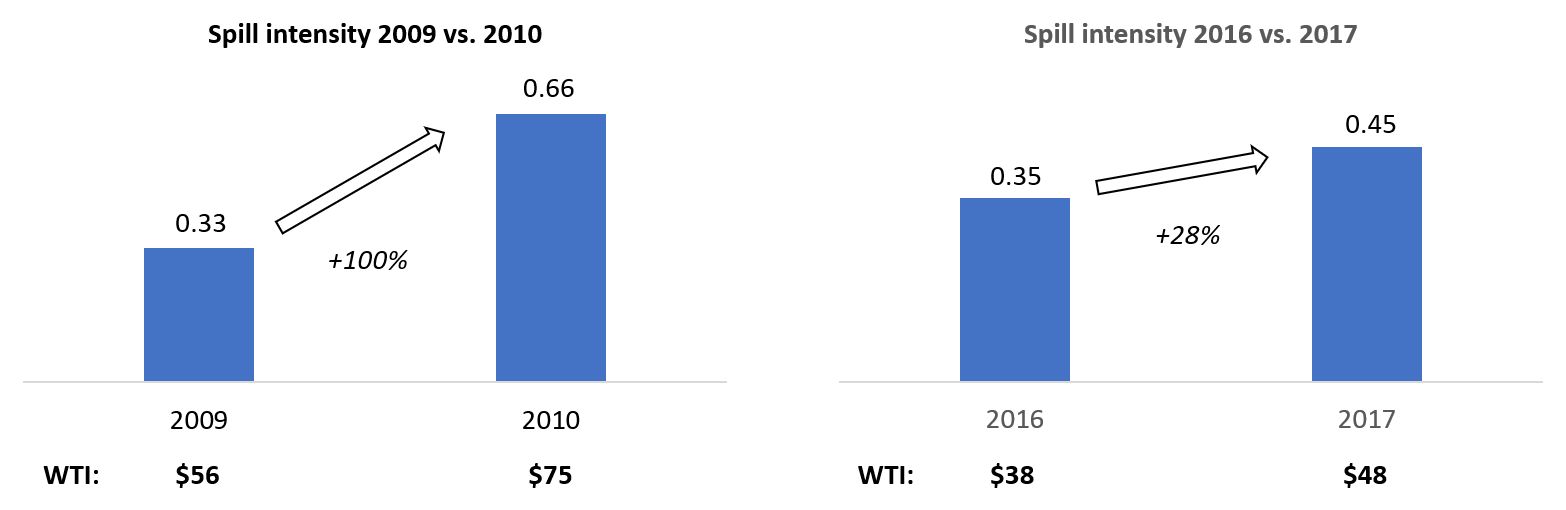

To make things worse, spill intensity tends to increase significantly during the recovery from an oil price downturn. So with oil prices hovering back around $40 after some pretty devastating lows these last few months, we may be in store for another spike in volume spilled.

We looked at spill data compiled by the Texas Railroad Commission during the last two oil price crashes and normalized spill volumes by production to compare apples to apples. What we found was a really interesting trend. Although the industry has generally become more efficient and spilled less oil and liquids over time, in the year after a downturn, spill intensity increased.

Explaining the trend

So what’s going on here? What we see is that when prices crash, companies delay maintenance, potentially cut costs out of corrosion prevention programs, and let go of lease operators. Now don’t get us wrong -- companies have to do this to survive, but this creates a difficult situation when prices rebound. Oftentimes senior employees are let go as they are the most expensive, and maintenance programs aren’t always reinstated to their pre-downturn level.

All these factors create an environment where possibly less experienced operators are going out to locations and bringing wells back online that they may not have been working before, with equipment that is a little older and might need some more maintenance.

Avoiding an increase in spills

This last price downturn has only lasted a few months so we might avoid the vicious cycle, but much of the same cost-cutting has taken place. But an increase in incidents does not have to be the case! Maintenance programs need to be reinstated, pump-by-exception implemented, and operators provided the training they need to be most effective in the field. A large number of shut-in wells will be brought online in the coming months, and steps need to be taken to prevent spill volumes from rising.

In general, the number of spills have declined as shale operations mature and more digital tools are implemented. With the right investments, we can keep spill volumes low as we recover from the latest downturn.