A digital twin is a virtual replica of a real-world location, piece of equipment, or process. It looks like your site. It behaves like your site. And it’s built to teach your people how to work safely in that environment without stepping foot into it.

Think of it as a sandbox version of your facility — fully interactive, risk-free, and endlessly repeatable.

A digital twin can replicate nearly any part of a manufacturing operation, from full production floors to individual pieces of critical machinery. It can mirror a production line, a warehouse layout, a loading dock, or even a compressor or dehydration unit for industrial facilities. It can also serve as a realistic new-hire orientation walkthrough, guiding employees through workflows, equipment locations, and hazard areas before they ever clock in.

In short, if it exists in your operation, it can exist as a digital twin with all the realism needed to train your workforce safely and consistently.

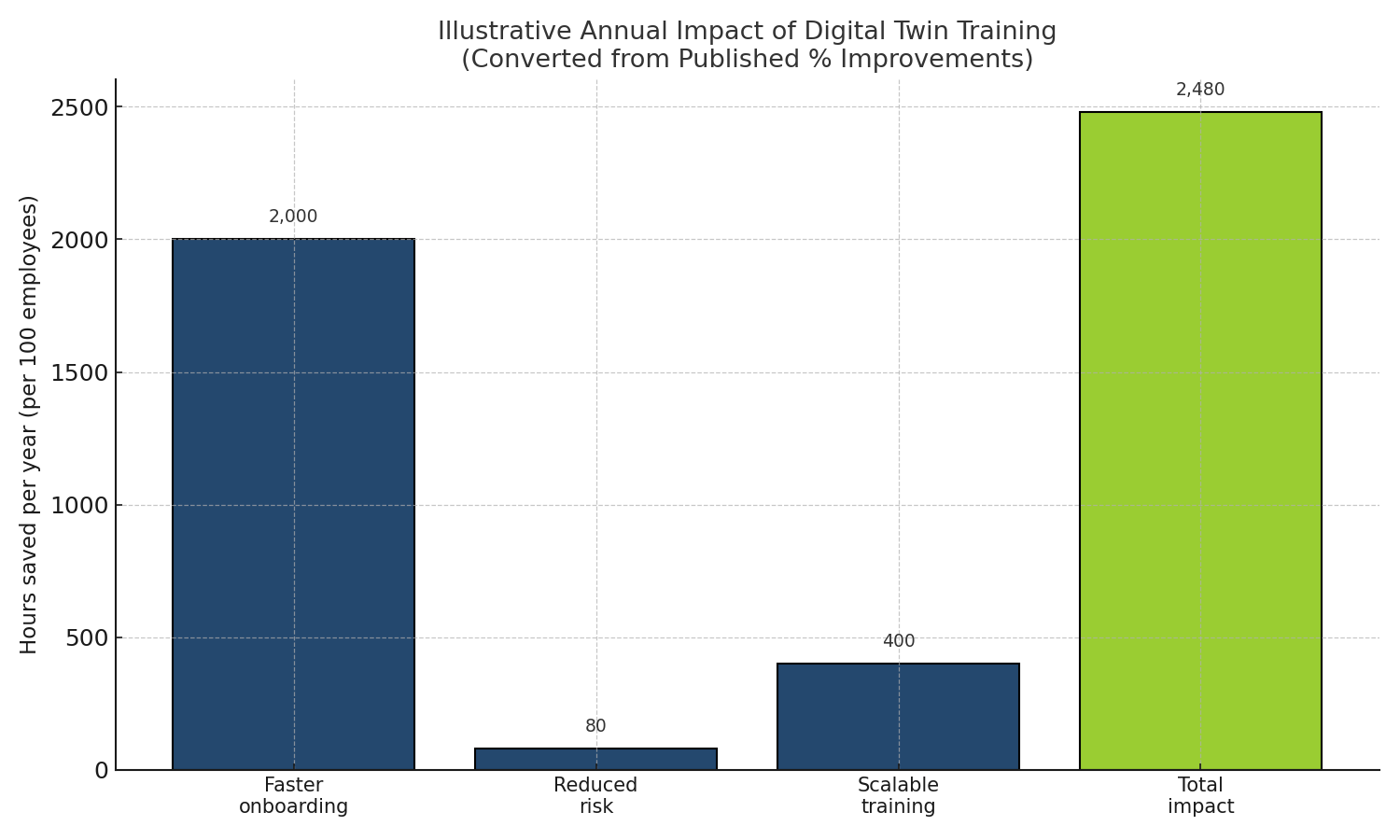

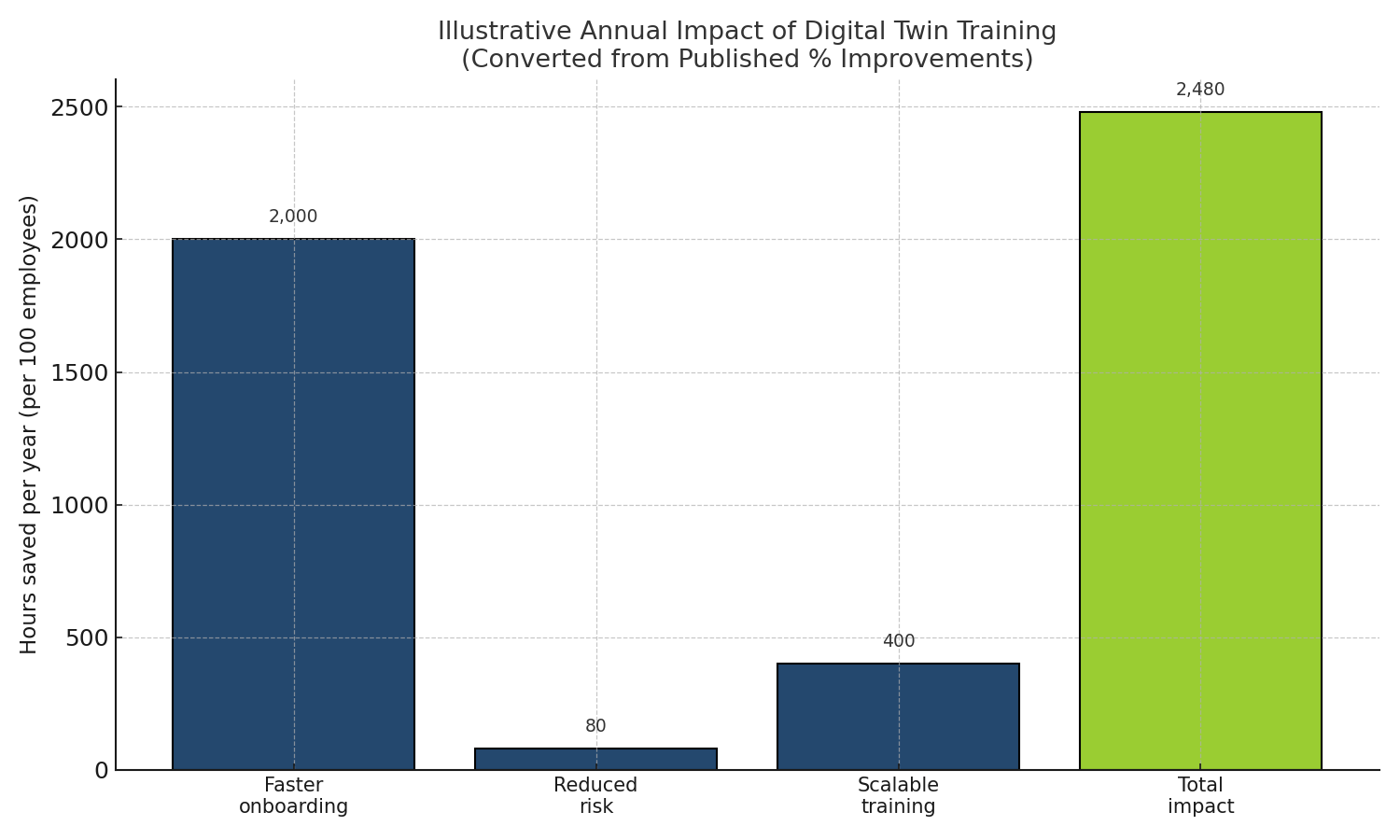

The value of a digital twin lies in how it elevates learning, giving teams a realistic environment to practice, build confidence, and develop the instincts they’ll rely on in the field. If your goals include faster onboarding, reduced risk, and scalable training, it’s a smart investment with long-term impact.

Digital twins reduce training time and expense by giving employees a realistic environment to explore before they ever hit the floor. New hires arrive already familiar with layouts, workflows, and key attention points which cuts downtime and accelerates competence from day one.

They also reduce operational risk. Employees can make mistakes, test decisions, and build instincts in a safe simulation instead of on live equipment. That confidence carries directly into real-world performance.

Because digital twins are fully scalable, the same asset can train your entire workforce without extra effort. With Wellsite LMS being browser-based, access is instant from any device, anywhere.

Ultimately, the power of a digital twin is in the realistic practice it provides, driving safer performance, faster learning, and a more modern approach to training.